- Details

ONE year on after the launch of the new Handypiece Pro sees it described as the best tool on the farm and in demand nationwide and internationally. It is now more powerful, lighter to hold with adjustable speed to suit all situations. Fly by wire shearing is now a reality with the new Handypiece Pro. Now 100 grams lighter than a standard handpiece with power to bum. The Handypiece Pro utilises powerful brushless motor technology, resulting in no more heat build-up than you get from a traditional wall powered plant.

Finally the Alpaca shearers will be able to use a traditional handpiece that is slim to hold but now with the speed that they can reduce to the same as a clipper. The Handypiece Pro has the added feature of variable speed from 2400 - 3500rpm. Dagging, crutching and trimming cows tails operate well at about mid speed of2700 rpm, while anyone wanting to get a nice cut while shearing can wind it all of the way up to 3500rpm. A new motor now means the battery lasts even longer as it is possible to crutch up to 350-400 sheep from one charge.

- Details

With the advent of portable electric hand pieces, gone are the days of having to transport a generator and shearing plant around the property, or to muster stock to the shearing shed. Although not intended to replace traditional machine shearing in sheds, portable shearing equipment can be useful for crutching mobs and shearing on the spot, ‘out the back’ away from power.

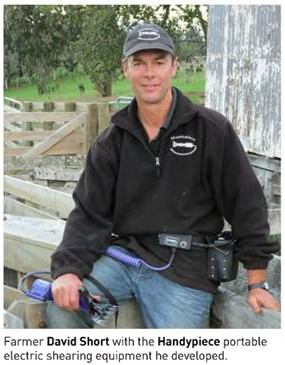

One of the innovators in this field is New Zealand farmer David Short who won the ‘Best Innovation’ award at Sheepvention’s farm invention competition in 2009 for his portable ‘Handypiece’ product. David says it wasn't long before the Handypiece found favour with many other farmers around his native New Zealand and then Australia, becoming famous for its slimline design, durability and ease of use.

- Details

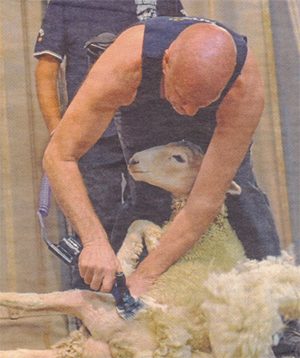

Have you any wool: World champion shearer David Fagan de-fleeces a sheep in record time at the speed shear competition at the Cheltenham Hotel on Saturday night. Fagan set the tone for the competition with a 20.8 second shear earlier in the night with a traditional handpiece. Fagan demonstrates Feilding inventor David Short's new Handypiece Pro, the latest version of his 12V portable shearing handpiece. Fagan completed the task in an impressive 23.9 seconds, leaving both inventor and shearer delighted with the result.

A vocal and supportive crowd of locals and internationals were on scene to catch an entertaining night of competitive speed shearing, leaving Fagan the popular winner on the night.

Photo and words: PETER RUBERY

Source: Feilding Herald

- Details

Gone are the days of having to drag all your sheep across the board to clean up.

Here's what Andrew Managh of Ratanui Farms had to say about the Handypiece; "We trade up to 30,000 lambs annually. Initially when we purchased our first Handypiece four years ago and I imagined that we would mainly use it for chasing fly strike around the farm which it was perfect for. As time progressed we found ourselves using it more and more for tiding up sheep before shearing and before they went to market," Mr Managh said.

"Now because of the usefulness Handypiece we have totally changed a major part of our farming operation. We built a second race beside our main drenching race and now that enable us to have two Handypiece operators bunging lambs before they go on the truck. There is less stress and damage to the animals plus it means we don't have to get the stock in twice"

Another sector of the market who have taken to using the Handypiece is stud farmers. Rams and big sheep are far more content to stand in a race while being cleaned up rather than getting turned over on their backs. Often rams are too big to drag.

The Handypiece kit comes with handpiece, lithium battery, charger, belt, holster and pouch all made from heavy duty leather, five meter extension cord, screw driver, oil bottle completed with a purposely designed carry bag.

Come and see for yourself what the Handypiece can do for you in the "Inventions Marquee" at the Hamilton Sheepvention or for more information call 1800 053 643

- Details

GONE are the days of removing your cows' tails to reduce the threat of milk contamination. The Handypiece is now an essential tool to be kept at the cowshed for tail trimming.

Here's what Max Houghton had to say about his experience with the Handypiece:

"We have owned another tail trimmer that was difficult to use and required a lot of energy to operate. I contacted Dave from Handypiece and asked if there was a chance if we could borrow a demonstrator to try on our heifers. The result was black and white. The Handypiece was very easy to operate: quiet, quick and it didn't matter if the tails were a matted mess. We did all our Heifers [about 150] and the battery was still going strong. Dave said he has had farmers get 300 cows trimmed on one battery charge. The other nice thing is that because the Handypiece uses standard sheep combs we could sharpen the blades on an old shearing grinder which is just down the road. We also have a couple of sheep running around the house so I can also keep them cleaned up"

The Handypiece is now well established worldwide in the sheep-care industry. Many farmers have described the Handypiece as "the Handiest thing you can have on a farm". Being designed around a traditional handpiece means it is slim to hold and being 12 volt means you can take it anywhere on the farm. It's perfect for keeping in your vehicle in times of fly strike but its main use is butting sheep up a race. Handypiece has a comprehensive website at handypiece.co.nz Come and see for yourself what the Handypiece can do for you at Agbits site H67, Mystery Creek.

- Details

SHEEP prices keep rising and, according to Dave Short from Handypiece Holdings, it's about time. "Finally farmers are getting the sort of money for their sheep they truly deserve," he said. The spin off from that is now farmers are happy to invest in quality capital farm equipment like the Handypiece to keep their stock clean and healthy, Mr Short said.

Since winning the major award for innovation at Sheepvention 2009, about I 000 Handypieces have been sold in Australia and New Zealand. Handypiece again found success in 2010, this time for the best improvement for equipment used for wool harvesting and shearing.

Mr Short said the award was a result of development surrounding purpose-designed Lithium batteries, which would be sold as an optional extra. Designed around a traditional handpiece means it's slim to hold and, being 12 volts, means farmers can take it anywhere on the farm.

"It's perfect for keeping in your vehicle in times of fly strike but its main use is butting sheep up a race."

The Handypiece has a sealed 12-volt electric motor-direct drive, attached to the back, which has the added advantage of being able to be used in the wet. This is unlike all other portable electric clippers that run a high speed motor through a gear box, which creates heat from friction and wear as the gears work together. Although suited to lifestyle and small block holders, Mr Short said 95 per cent of Handypiece sales have been to large scale farmers.

The rechargeable 7 Ah battery will provide enough power for about 120 sheep crutchings.

"There are two batteries in the kit so you can get up to 240 sheep depending on how dirty they are.

"After that you have the option of plugging in the five metre extension cord to your quad, ute or other 12v supply."

The Handypiece has a reset fuse for overload or lockup. The kit also comes with a battery charger, belt, holster and pouch all made from heavy duty leather, completed with a purposely designed carry bag. Following the closure of the Supershear (Sunbeam) factory in Australia, Handypiece Holdings Ltd has secured a supply of quality Lister Handpieces, which in turn will become the new green Handypiece kit.

Source: The Land

- Details

The first traditional shearing handpiece that is battery operated, hangs in a small sling on a belt, and can be taken out in the yards or paddock, has hit the Australian market.

New Zealand farmer David Short, pictured, has spent four years coming up wih the right design.

This year he made the trek from the Manawatu town of Feilding to Hamilton Sheepvention in Victoria, Australia, to enter the handpiece in the inventors competition, which he subsequently won.

David said the handpiece would be ideal for cleaning up fly-struck sheep in the paddock.

He has sold 430 sets so far in NZ, mostly to large-scale, not hobby, farmers.

As a lamb trader, he said he wanted something light, quick and easy that he could take into the yards to clean up the sheep before putting the sheep on the truck.

"And I wanted to use the traditional handpiece shape, as it is the best ergonomically, better than electronic clippers," he said.

Made from steel, the tool is the first portable, low-voltage mechanical handpiece.

Short said it was a low-cost alternative to other traditional electric clippers that relied on mains power or a 12-volt battery.

The motor of the handpiece can be battery pack-operated, attached to a belt, or connected to a vehicle.

- Details

Dave Short lay broken on the side of Cameron's Line, wishing he could turn the clock back one minute.

At that point he would have been close to fulfilling one of his dreams-not nursing more than 12 broken bones and unable to move.

That dream was the launch of his Handypiece shearing device into the national and global market.

Dave had invented and manufactured the handpieces and was delivering 30 of them from Feilding to Palmerston North on August 1 - the eve of his new business alliance as a supplier to Tru-Test Supershear.

But one handpiece had fallen off his truck.

Dave (45) pulled over; ducked across the road and recovered the piece, inspecting the damage.

His last panicked thought as he heard the screech of tyres from an oncoming car was: “Hell, this is going to hurt."

It collected him at 70km/h. His wild leap in the air threw him on to its bonnet and windscreen and from there to the gravely roadside.

The bent handpiece was now the least of his worries.

With an off-duty doctor and nurse among the first on the scene, Dave - who was conscious throughout- had the clothes cut from his body, limbs realigned while dealing with a gnawing fear that he was paralysed.

"I honestly felt like I was in a Clint Eastwood movie,” he says.

Police told Dave that his last-minute leap possibly saved his life.

When the nurse at the scene phoned his wife Jacky, she was told Dave had been in a car accident and broken his ankle.

She and the couple's three children, Jake (15), Ashleigh (12) and Tom (10), passed the accident scene on their way to Palmerston North Hospital and had the dawning realisation that the situation was serious.

Jacky's biggest fear was that her husband had suffered brain injuries.

"I knew I could cope with wheelchairs, but I wanted him to still be him."

She then felt overwhelming responsibility for the whole family as Dave was placed in an induced coma for four days while his injuries were assessed and he was stabilised.

Upon waking, he stilled the family's fears that he wouldn’t still be Dave by giving his father instructions on feeding the stock. But the list of injuries was daunting.

Tendons were ripped from his left thumb, his upper left arm was broken, Dave's cheekbone, eye-socket, leg, neck and skull were all fractured, and his right ankle was rendered useless by a compound fracture.

Five weeks of hospitalisation followed, but support flooded in from day one.

Friends and family took over the daily stock work on the couple’s 60-hectare sheep and beef farm.

Townsfolk expressed their desire to help in a practical way by delivering an abundance of food, while grandparents, schools and friends provided much-needed support for the children.

''I honestly felt we had become a community project,'' says Jacky who had taken leave from her job as electoral agent for MP Simon Power and the volunteer community organisations she is heavily involved in.

The number of visitors to the hospital resulted in an orderly asking if Dave was famous.

“Famous in Feilding" his wife replied.

However it was the couple's determination for "business as usual" with Handypiece that provided the greatest challenge.

Winner of an innovation award in 2006, the Handypiece is the first portable, lowvoltage mechanical handpiece of its type to be designed and proven in a work situation. The alliance with Tru-Test marked the beginning of the next phase in supplying it beyond local markets.

With contracts signed to supply Handypiece to Tru-Test as demand dictated, Dave says the support of the company was crucial.

"They even supplied workers from their gate-making factory in Bunnythorpe to get us through the first couple of weeks after the accident,” he says.

Extra staff were employed for the manufacturing workshop and Jacky began relaying each day's orders and enquiries from home to hospital, holding Dave's mobile phone to his ear as he co-ordinated suppliers and ordered parts.

Dave says he was fortunate his 70-year-old father had watched the business grow and was able to step in.

Tru-Test Supershear development manager Matt Langtry says news of the accident was a shock.

“It was gut-wrenching with it happening so close to the launch. We felt for Dave and Jacky."

He says the production/marketing alliance came about after True-Test recognised the uniqueness of Dave's product and saw how they could promote it to a larger market nationally and globally.

"There has already been considerable interest from markets in the UK and Australia,” he says.

Matt says Tru-Test staff and management admired the couple’s determination to carry on and are thrilled that production is back on schedule.

"Dave is a bit of a rubber band in more ways than one,” he says.

After a short detour to the woolshed on his way home from hospital “to tell my mates they were silly buggers and I would have got the shearers in", Dave is now recuperating at home.

He has months of specialised physiotherapy ahead of him and battles headaches and fatigue daily.

The long-term prognosis for his lower right leg is uncertain, but Dave is philosophical about the possibility of losing it.

"I'll just invent something to get me out and about," he says.

For 20 years Dave built replica Lamborghinis for the export market, so this is no idle boast.

One unanticipated outcome tor the family was the financial cost they now bear.

"Being self-employed, having taken on debt to get the business going and pouring all earnings back into the business, once calculations were done for insurance and ACC payments, we found ourselves disadvantaged” says Dave.

He advises anyone starting a business to look at ways of collecting a regular wage or to take out an insurance or ACC policy that guarantees a definite amount for living expenses.

"The premiums would be worth it, for peace of mind," he says.

Jacky is quick to add that ACC have dealt with them compassionately and provided child-care and house-keeping support which enabled her to help with Dave's care in hospital and, more recently, for her to return to work.

Of course the cost of major road accidents stretches beyond support during recuperation and the price of emergency and medical care.

Dave agrees that a social cost is paid in the loss of quality of life and productivity.

"There are so many effects on the family beyond the financial. Loss of mobility, the emotional effects on children, business worries and the 'unpaid' care-giving role of family members."

And he doesn't even know where to start paying back his mates that stepped in to run the farm.

"I also recommend having a very>' capable wife who can organise everything when you are out of action”.

He misses being involved in sport with his children, having full mobility, being out on the farm, in his workshop and living without pain.

As an example of some of the life-changing decisions he has made his super-quad racing bike is about to be sold.

An easy decision, he says, despite past recreational activities that include racing his Lamborghini in the Targa of New Zealand rally and spending the past few years tearing up and down hills on his super-quad, hiding injuries from his wife.

"I suspect if I had injured myself through racing I would have been lucky to receive one visit to hospital in five weeks instead of two a day from Jacky”

Dave has agreed to a drop in speed in his daily life from 99km/hour each day to 85km/ hour in recognition that it is time to slow down a bit.

"I could not put my family through this again, so for the foreseeable future I am playing it safe."

Shades of the old Dave emerge, however, as he adds: "That's a fairly safe quote really that shouldn't come back to bite me."

He is much more thankful about life now that he knows how easily and quickly it can be taken away.

"At the end of the day, my business is alive and so am I."

Source: Farmers Weekly Country-Wide